Facilities

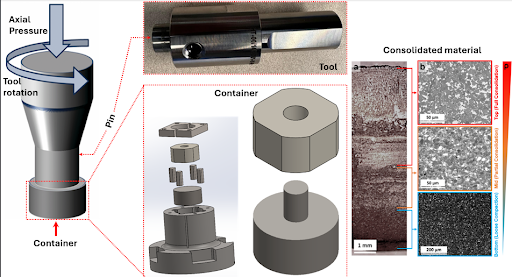

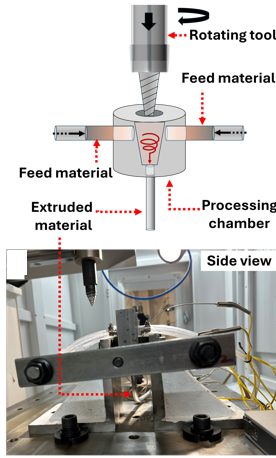

Friction Stir Laboratory

A suite of solid-state metal manufacturing capabilities:

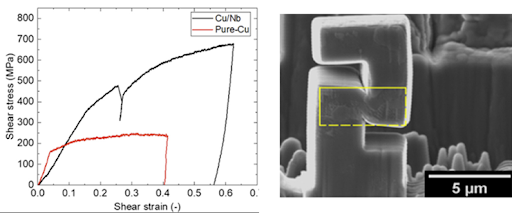

Nano Mechanical Testing and Characterization Laboratory

Our Nano mechanical testing (PI 89 SEM PicoIndenter) can perform mechanical characterization on small-scale samples at temperatures up to 1000°C. The PI 89 has in-situ heating elements on the probe and sample that allow for indentation at elevated temperatures. The PI 89 also has cryogenic temperature options that can perform quantitative in-situ nanomechanical testing at temperatures down to -130°C

Our expertise in meso-nanoscale characterization allows a multi-length scale analysis of our materials.

Center of Additive Manufacturing and Logistics (CAMAL)

- Apparatus for Hot and Cold Rolling of materials

- Facilities for Additive Manufacturing (available as a shared resource).

- Shot Peening Surface Treatment.

- Furnace for Annealing with a regulated atmosphere

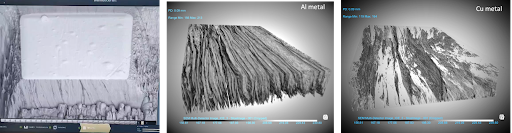

- Scanning Electron Microscope (SEM) capabilities

- ThermoFisher Titan 80-300: High-precision Scanning Transmission Electron Microscopy (STEM) with aberration correction

- Atomic Force Microscope (AFM)

- Plasma-Focused Ion Beam (FIB) instrumentation

- Squid and PPMS

- X-ray diffraction (XRD) analysis tools

- Facilities for cryo and high-temperature mechanical property testing

- High-speed cryo ball milling

- Electro Polishing