Research

The Gwalani Research Group specializes in engineering alloys and composites optimized for durability in severe conditions. We design materials that maintain their integral structural characteristics, including robustness and resistance to oxidation while preserving essential functional attributes like electrical conductivity and magnetic properties.

Sustainable Manufacturing

We focus on minimizing the environmental impact of metal processing by conserving energy and resources. Key strategies include energy efficiency, reducing waste, using clean technologies, and promoting eco-friendly product design.

Cost-Effective Manufacturing Routes

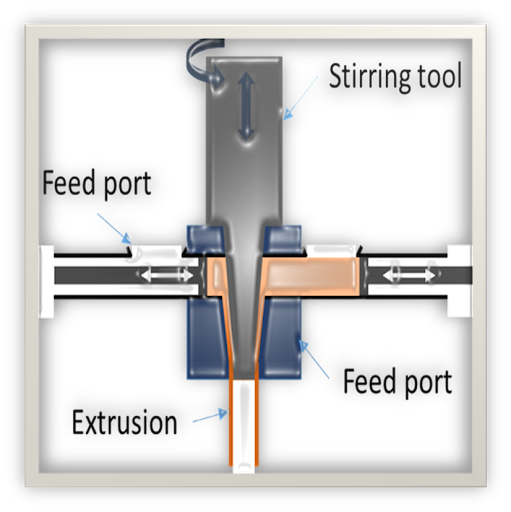

Our manufacturing processes are designed for cost-efficiency and energy savings, focusing on microstructural modification and alloy composition through deformation-based processing techniques. We employ friction-assisted solid phase processing methods to produce non-equilibrium and compositionally graded alloys

Recycling Technologies

Our method involves high-speed stirring of metallic scrap, which leads to frictional and adiabatic heating, followed by consolidative extrusion (Solid Stir Extrusion, SSE). This process allows us to create multi-material and multifunctional structures without bulk melting, providing an attractive solution for the eco-friendly recycling of complex waste streams and the advancement of advanced alloys/composites.

We promote reuse, recycling, and upcycling throughout the product life cycle by implementing less labor-intensive sorting techniques and addressing complex waste issues. This interdisciplinary research bridges manufacturing, characterization, and nuclear domains, nurturing the growth of a versatile, multidisciplinary manufacturing workforce.

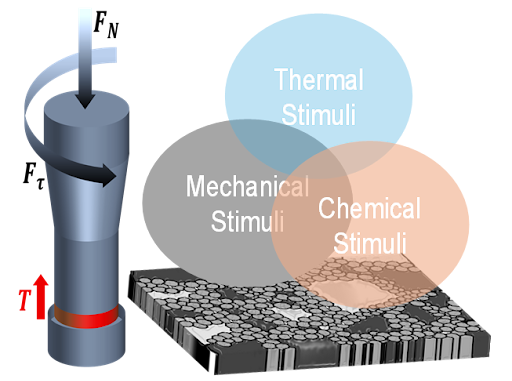

Multi-Stimuli Processing

Solid State Reactive Processing

Advanced Alloys for Extremes

Alloy Design for Equilibrium and Non-Equilibrium Processing Routes

Our alloy design approach includes computational modeling based on solution thermodynamics tailoring compositions and processing routes to achieve desired material properties, considering both equilibrium and non-equilibrium conditions.

Design Strategies include:

- Composition selection informed by thermodynamic modeling

- Heat treatment and thermomechanical processing cycles

- Microstructural control by designing heat treatments for specific microstructural templates

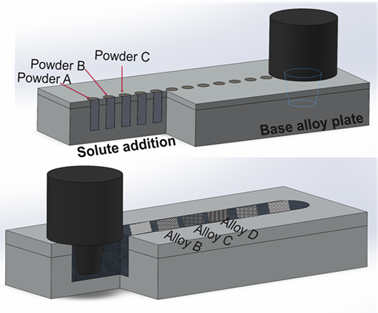

High-Throughput Techniques for Material Discovery

Rapidly generating and screening a large number of material compositions and processing conditions to identify those with desirable properties.

Our approach aims to create combinatorial material libraries, automated friction stir systems, In-situ monitoring, and characterization, and use Design of Experiments (DOE) for a comprehensive exploration of material and process space.

Mechanistic Understanding of Material Vulnerabilities

Our approach combines ex-situ and in-situ methods to observe materials at the mesoscopic to atomic scale in real-world conditions. We focus on dissecting the root causes of defect formation and the mechanisms behind material failure through comprehensive multi-scale characterization. Our expertise lies in devising tailored compositional and processing strategies to advance the development of future-oriented materials.

Probing Materials at Multiple Length Scales

The multi-scale approach involves examining materials from the atomic and molecular level up to the macroscopic level, providing insights into how different length scales influence material characteristics.

Diverse Testing Modalities

We conduct tensile, compressive, and shear tests under various temperatures and environments.

Nano-Scale Property Assessment

Our use of precise, site-specific in situ testing methods enables us to evaluate localized properties meticulously. Our nano-mechanical testing facilities allow us to introduce and monitor well-defined defects, allowing for detailed analysis of the material’s response.

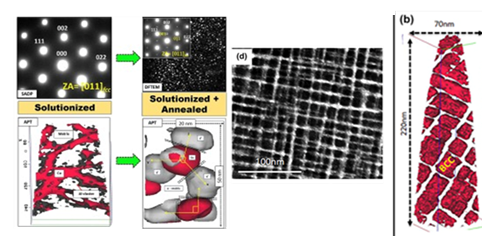

Transmission Electron Microscopy

Correlative Atom Probe Tomography

Selected Publications From The PI

Bharat Gwalani, Jia Liu, Sten Lambeets, Matthew Olszta, Jonathan Poplawsky, Amit Shyam and Arun Devaraj. Rapid Assessment of Interfacial Stabilization Mechanisms of Metastable Precipitates to Accelerate High-Temperature Al-Alloy Development. Materials Research Letters, 10:12, 771-779, 2002.

Bharat Gwalani, et al. Modifying Transformation Pathways in High Entropy Alloys or Complex Concentrated Alloys Via Thermo-Mechanical Processing. Acta Materialia 153: 169-185, 2018.

Bharat Gwalani, Matthew Olszta, Soumya Varma, Lei Li, Ayoub Soulami, Elizabeth Kautz, Siddhartha Pathak, et al. Extreme shear-deformation-induced modification of defect structures and hierarchical microstructure in an Al-Si alloy. Communications Materials 1, no. 1: 1-7, 2020.

Bharat Gwalani, Sindhura Gangireddy, Shivakant Shukla, Christopher J. Yannetta, Sheena Grace Valentin, Rajiv S. Mishra, and Rajarshi Banerjee. Compositionally Graded High Entropy Alloy With A Strong Front and Ductile Back. Materials Today Communications 20: 100602, 2019

Bharat Gwalani, Sriswaroop Dasari, Abhishek Sharma, Vishal Soni, Shivakant Shukla, Abhinav Jagetia, Priyanshi Agrawal, Rajiv S. Mishra, and Rajarshi Banerjee. High Density of Strong Yet Deformable Intermetallic Nanorods Leads to an Excellent Room-Temperature Strength-Ductility Combination in a High Entropy Alloy. Acta Materialia 219: 117234, 2021.