This fall the MSE department hosted its bi-annual visual competition to foster positive morale and encourage a supportive spirit of faculty, staff, and students. After a competitive and nail-biting review by the judging panel, the winners have been selected and we are excited to announce them.

Tip: Click on the images to see the incredible detail.

The Winners Are…

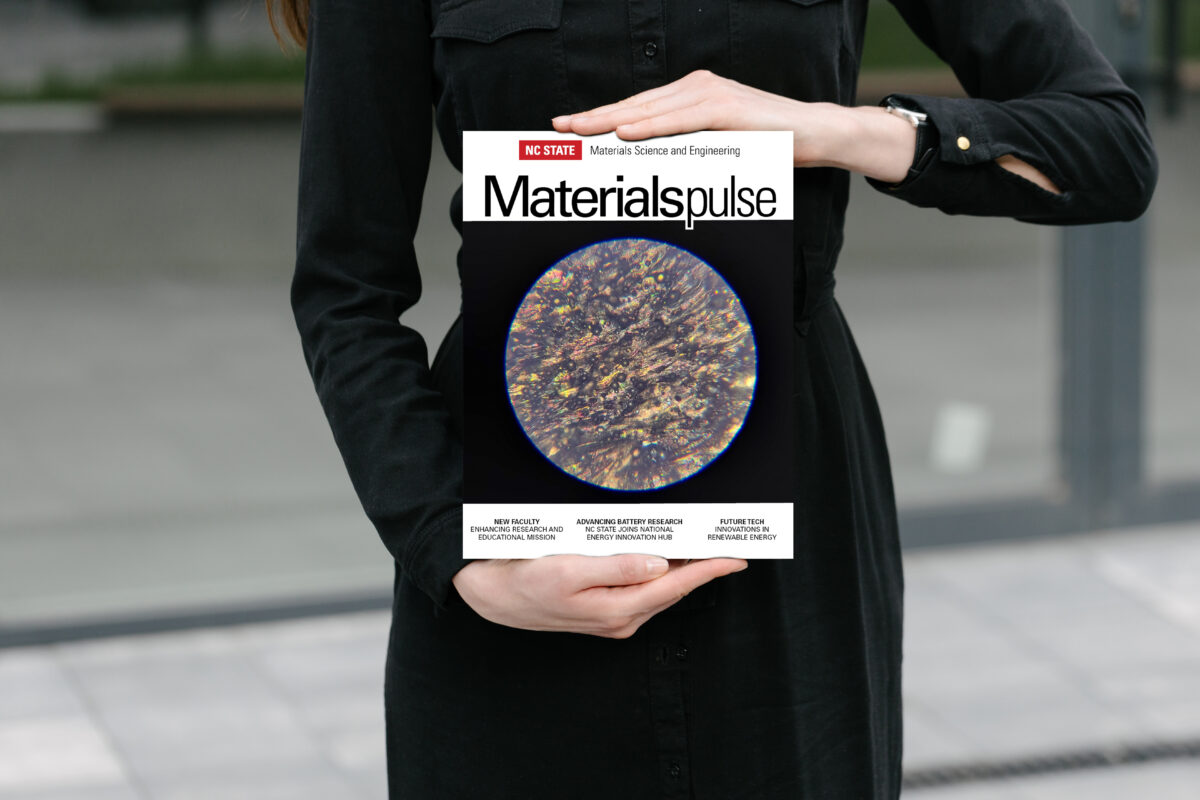

Main Competition for the MSE Atrium

Sofia Antinozzi won the main visual competition, which was open to all MSE faculty, staff, and students. Her entry is a photograph titled “Corrosion on Pre-Ground AM Steel.” The judges were excited to see the level of detail, colors, and texture visible at 100x magnification. Sofia is an undergraduate researcher in the Gwalani Research Group.

Artist Statement

“This photo of corrosion on the rough surface of an unground additively manufactured steel sample highlights how surface texture and microstructure affect corrosion resistance in AM materials. The rougher the surface, the worse the corrosion, and the more beautiful the picture! The alloy pictured was created to be sea-worthy for the US Navy, so it was polarized in a saltwater solution to corrode, and then photographed on an optical microscope at 100x magnification. This highlights the crucial role materials science has in enhancing the longevity and functionality of advanced materials, and the importance of materials engineering to develop optimized alloys and treatments for specific applications.”

Main Competition Runner-Up

Sergei Rigin is the runner-up winner of the main visual competition. His entry is a simulation titled, “Polymer Forest.” The judges were awestruck by the material’s resemblance to a wooded forest. Sergei is a graduate researcher in the Yingling Research Group.

Artist Statement

“The work highlights the visual resemblance between polymer structures found in the microworld and human-scale objects, such as forests, illustrating nature’s capacity to replicate its artistic patterns across different scales. The image is a snapshot from a molecular dynamics simulation of a polymer brush—a set of polymer chains grafted to a surface at one end. This material is widely used in various fields of materials science, particularly surface science, to provide desired adhesion, friction, and surface reactivity.”

In addition to Sergei’s piece to be installed in the atrium, his entry was also included on the back cover of the department’s 2024 Materials Pulse magazine.

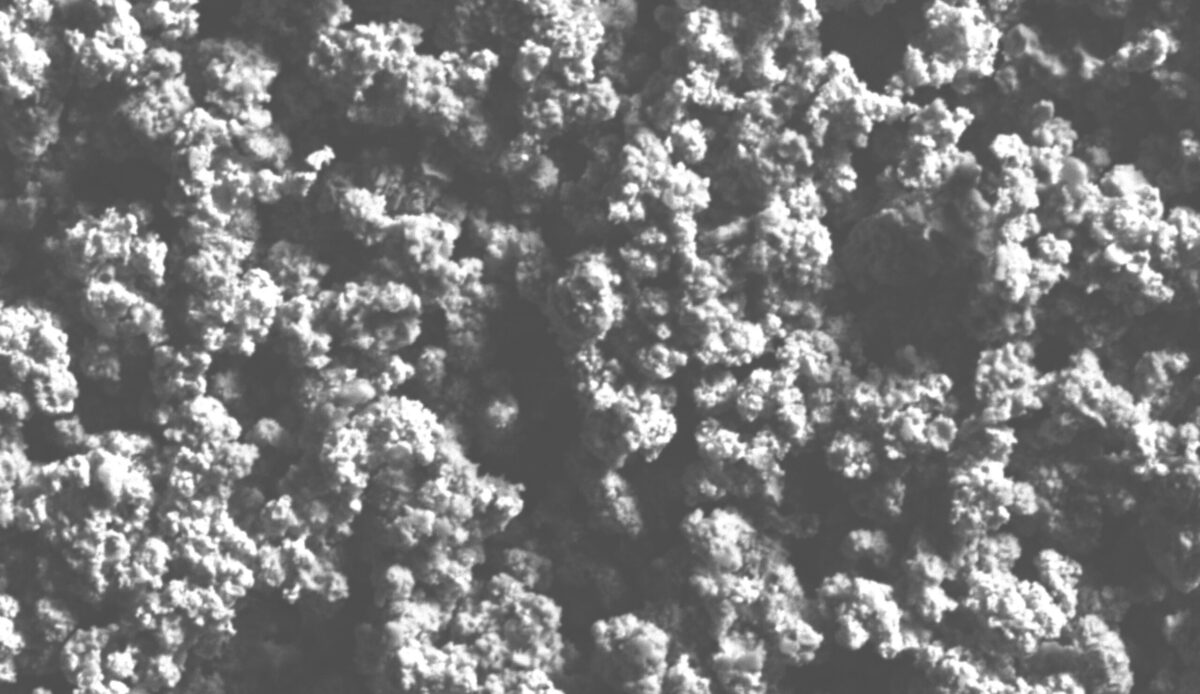

Sub-Competition for Undergraduate Lounge

For the sub-competition of the visual entries open to undergraduate MSE students only, the winner is Nethra Vasudevan. Her entry is a micrograph image titled, “Ni@Au Core-Shell Microparticles in SEM.” The judges were impressed with the texture which resembled an aerial view of a forest. Nethra is an undergraduate researcher in the LaBean Research Group.

Artist Statement

“These Au@Ni core-shell particles were synthesized this semester using a redox transmetallation procedure. The particles were analyzed under the SEM to see if gold coating occurred to the microparticles. Particle synthesis is part of ongoing research in the LaBean lab, done by Mary Hoult and myself, two seniors in MSE. The goal of this research is to use these coated particles to make magnetically aligning anisotropic wires in a settable matrix, that could have applications in reducing the labor and time required to make connections between Ball Grid Arrays and Printed Circuit Boards. This image is a result of using an SEM unguided for the first time, which led to some experimentation with settings and a lot of laughter as Mary and I took turns to take images. Most of our time spent in the lab is filled with laughter as we test out methods and push forward towards our research goal; this image is a result of the hard yet fulfilling process.”

Nethra’s entry will be printed and installed in the undergraduate student lounge.

A record number of entries were submitted in the Fall 2024 visual competition. The judges recognize the following groups of honorable mentions, with a future date of gallery wall installations.

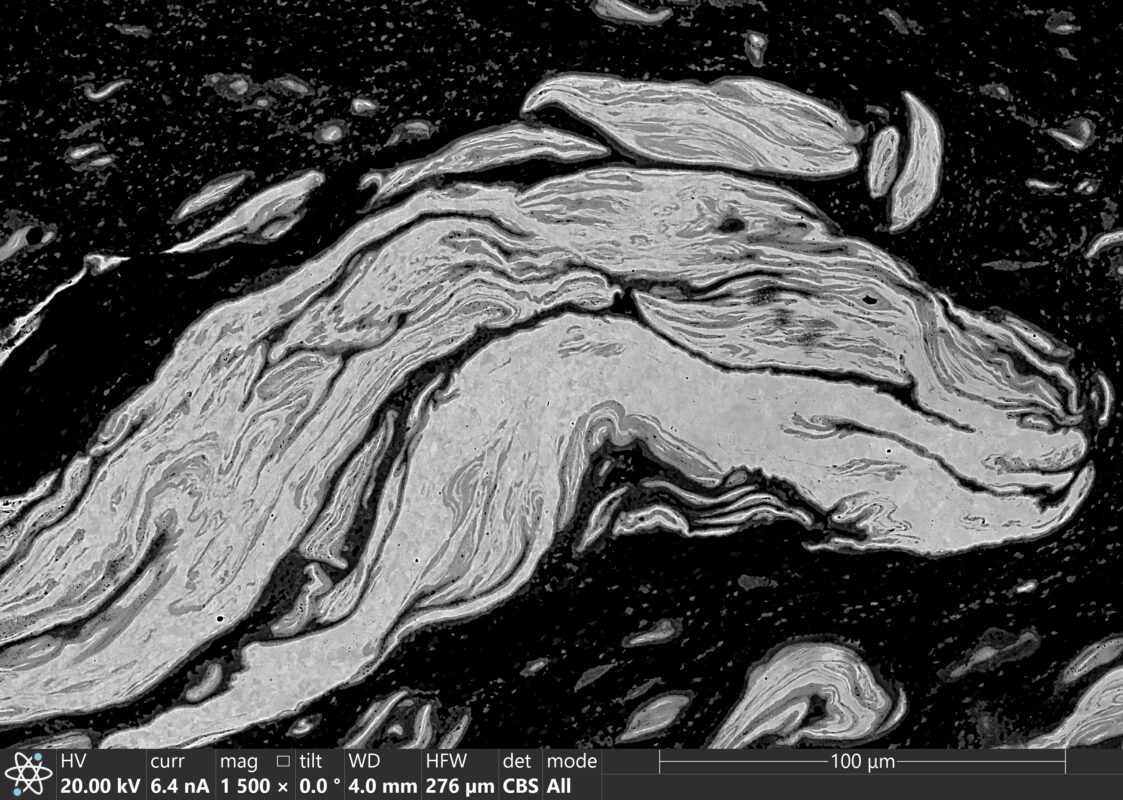

Md Jasim Uddin, a graduate student in the Gwalani Research Group, created this micrograph on September 10, 2024. His work focuses on friction stir processing (FSP) of aluminum (Al) alloys with embedded copper (Cu) powder. During FSP, severe plastic deformation promotes the formation of Al-Cu intermetallics, such as Al₂Cu, which significantly enhance hardness and wear resistance compared to the base alloy. The high thermal shear and plasticity involved cause the Cu particles and Al matrix to undergo plastic deformation, resulting in unique intermetallic structures. The featured image captures a dragon-shaped intermetallic formed during this process.

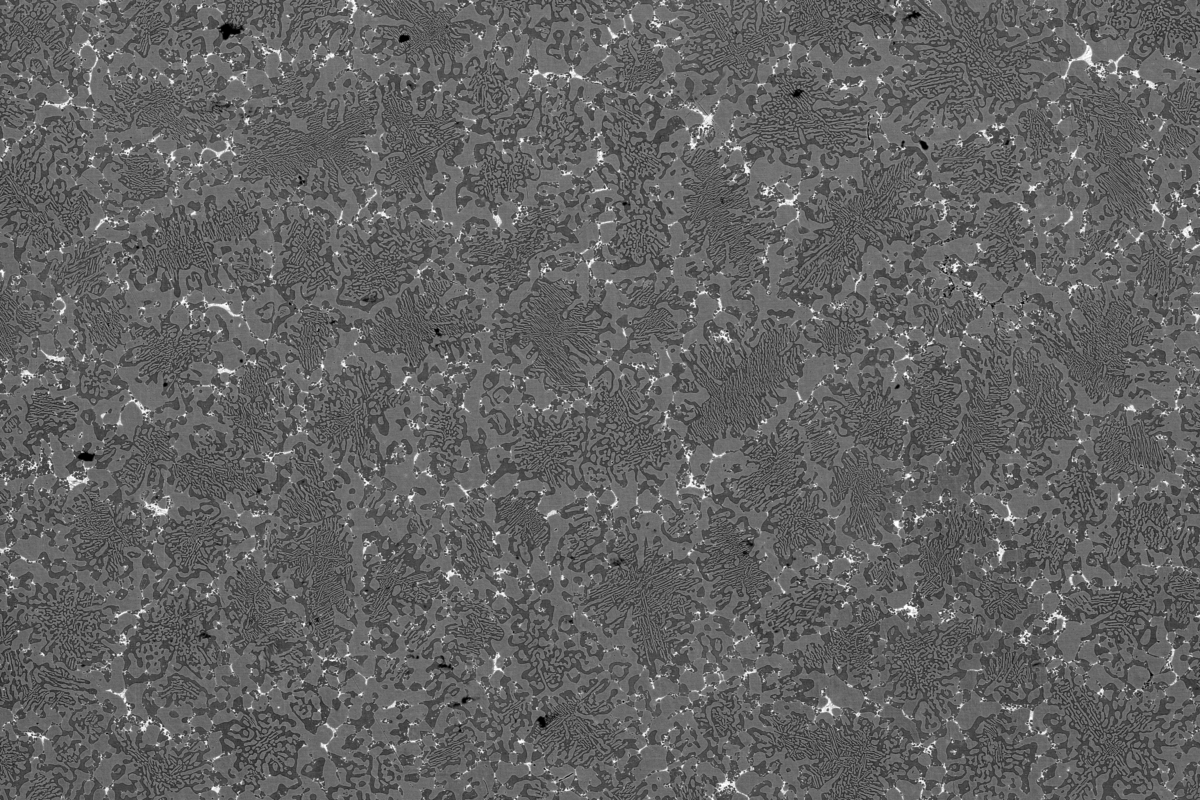

Michael Lastovich, a graduate student in the Gwalani Research Group, presents this micrograph titled “As-cast microstructure of a Multiphase AlCoCrFeNi(CuTiZr) High Entropy Alloy.” Modern research in high entropy alloys (HEAs) has moved beyond the pursuit of single-phase stability to explore multiphase compositions, such as the FCC+BCC duplex structures depicted here. These multiphase systems exhibit exceptional strength and ductility in minimally processed states, owing to the inherent phase stability of these concentrated alloys, even under elevated temperature conditions.

Fu-Yun Tsai, a postdoctoral researcher in the Gwalani Research Group, presents this micrograph titled “Threads of Strength: Boron Nitride Nanotubes Weaving in Ti Matrix.” This work highlights the fusion of nanotechnology and advanced manufacturing, showcasing the embedding of boron nitride nanotubes (BNNTs) within a titanium (Ti) matrix using Electron Beam Powder Bed Fusion (EB-PBF). The scanning electron microscope (SEM) image reveals the intricate structure of the composite, emphasizing the precision achieved through modern additive manufacturing. This innovative approach demonstrates how integrating nanomaterials with electron beam technologies can enhance the mechanical properties of metals, paving the way for stronger, more resilient materials.

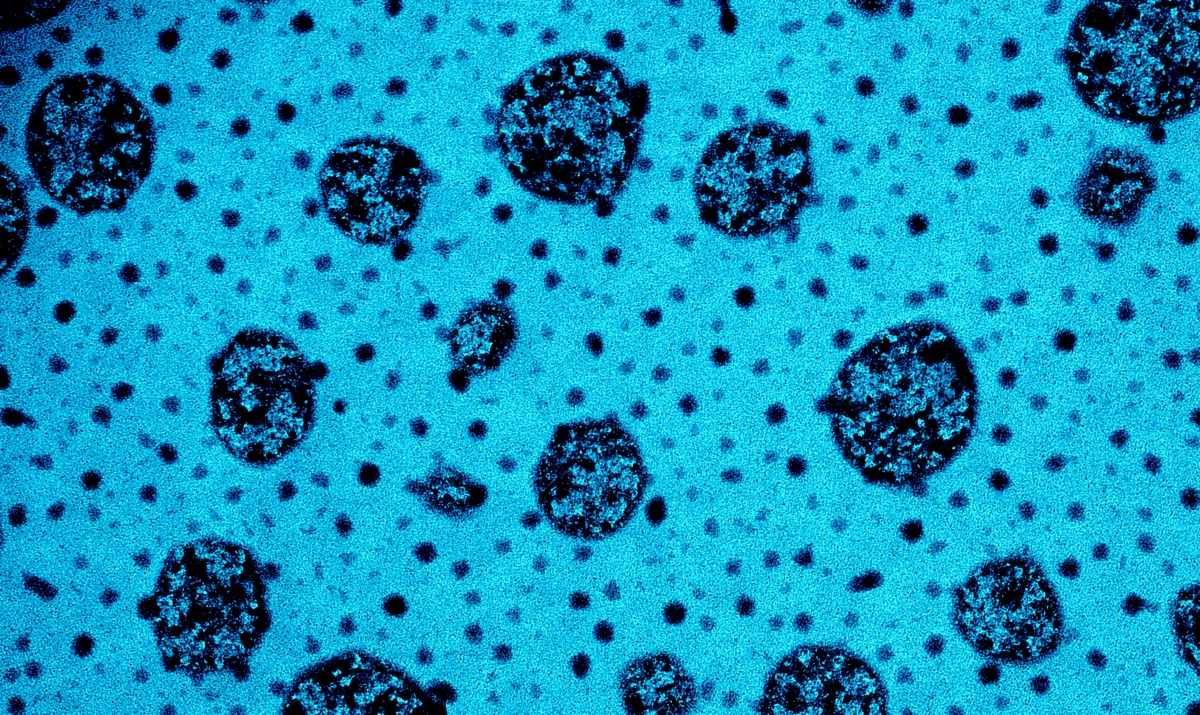

Fontaine McFeaters, a graduate student in the Spontak Research Group, presents this micrograph titled “Frozen in Time: A Snapshot of Self-Assembly and Aggregation.” The transmission electron microscopy (TEM) image captures the coexistence of self-assembled micelles and aggregate structures formed by an amphiphilic block polymer after prolonged exposure to a selective solvent. This production of nanostructures represents a novel finding in the field. The image was achieved by freeze-drying the solvent on a carbon-coated TEM grid after polymer exposure, followed by selective staining to enhance contrast and detail.

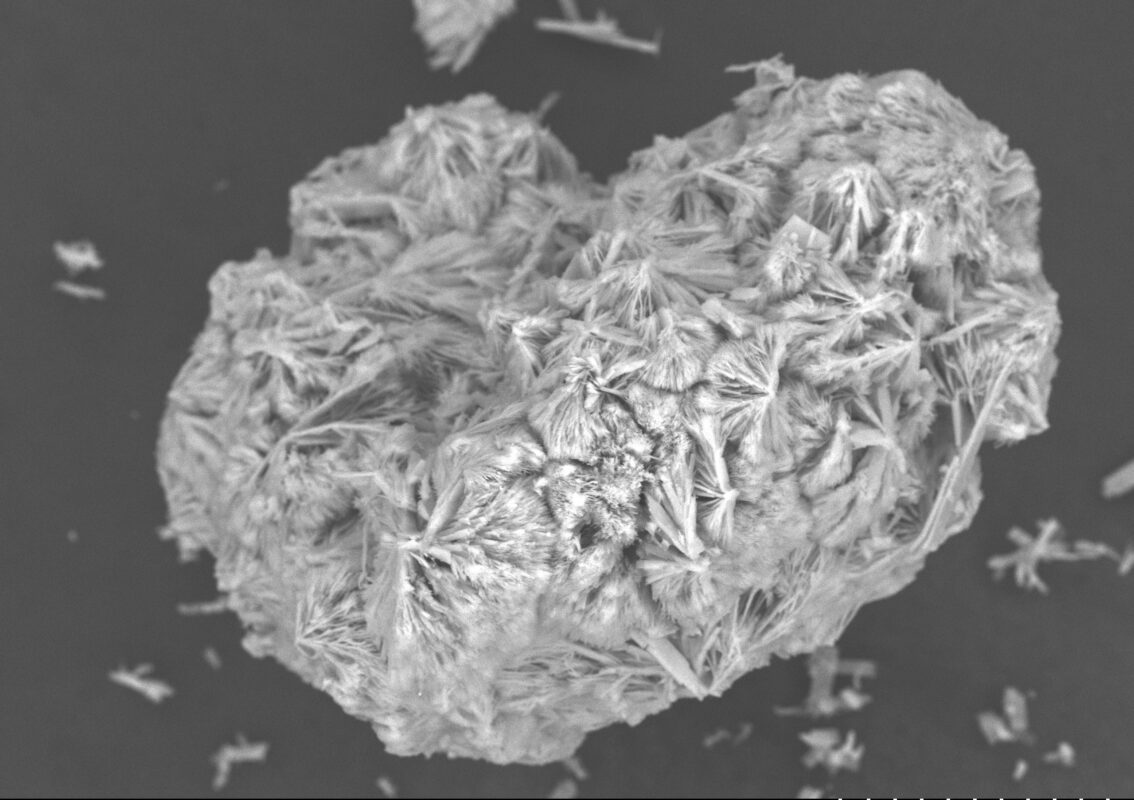

Darrell Harry, a graduate student in the Jones Research Group and the STEPS Center, presents this micrograph titled “Heart-Shaped Zinc Phosphate Cluster.” Captured using a Scanning Electron Microscope (SEM) with back-scattered electrons, the image exemplifies the foundational MSE principle of structure. It offers a high-resolution view of the material’s microstructure, highlighting the intricate crystal growth patterns. By employing electrons to examine the surface morphology, this image provides valuable insights into the arrangement and formation processes of the crystal structure.

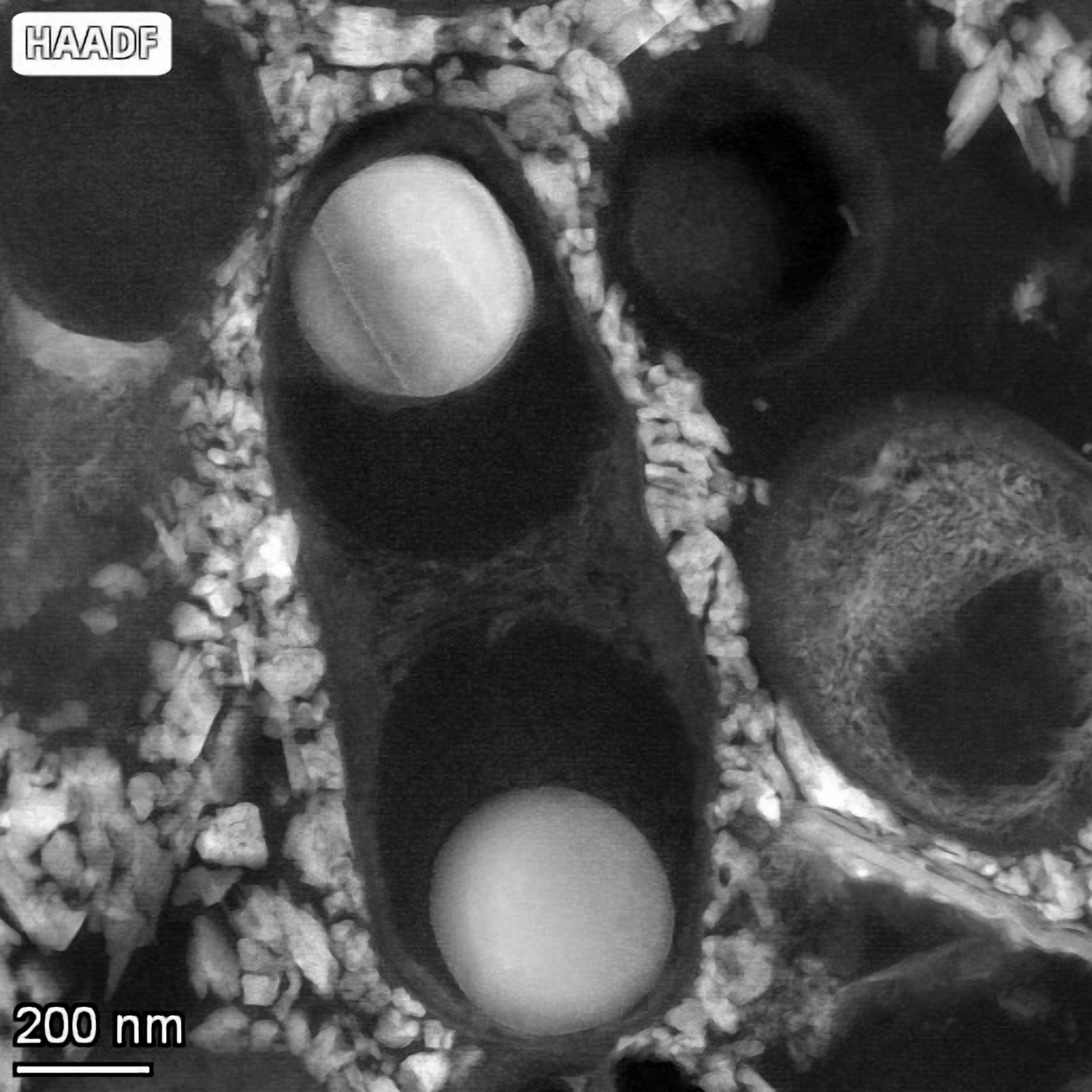

Elizabeth Trubchaninov, a graduate student in the Jones Research Group and the STEPS Center, presents this micrograph titled “Polyphosphate Granules Identified in Sewage Sludge.” This work explores the challenges of preparing biological material for electron microscopy (EM) by examining sample preparation techniques and their impact on morphology and elemental composition. Focusing on phosphorus-accumulating organisms (PAOs) in activated sewage sludge from a wastewater treatment plant, the image highlights a sample prepared through chemical fixation, post-fixation, osmium tetroxide and uranyl acetate staining, and sectioning over ethylene glycol.